An automated supply replenishment system is a technology-driven solution designed to streamline inventory management by automatically monitoring stock levels and placing replenishment orders. These systems improve efficiency, reduce human error, and help businesses maintain optimal inventory levels, avoiding overstocking and stockouts. Using data analytics and real-time insights, companies can quickly respond to changing demand patterns, enhancing customer satisfaction and operational performance. This article explores the workings, benefits, and best practices of automated supply replenishment systems, offering insights into how they can transform supply chain management.

Understanding automated supply replenishment systems

Automated supply replenishment systems are crucial for managing inventory by automatically placing orders when stock levels drop below a set threshold. The primary goal is to maintain optimal stock levels, reducing the risk of stockouts and excess inventory. This improves operational efficiency and customer satisfaction by ensuring products are available as needed.

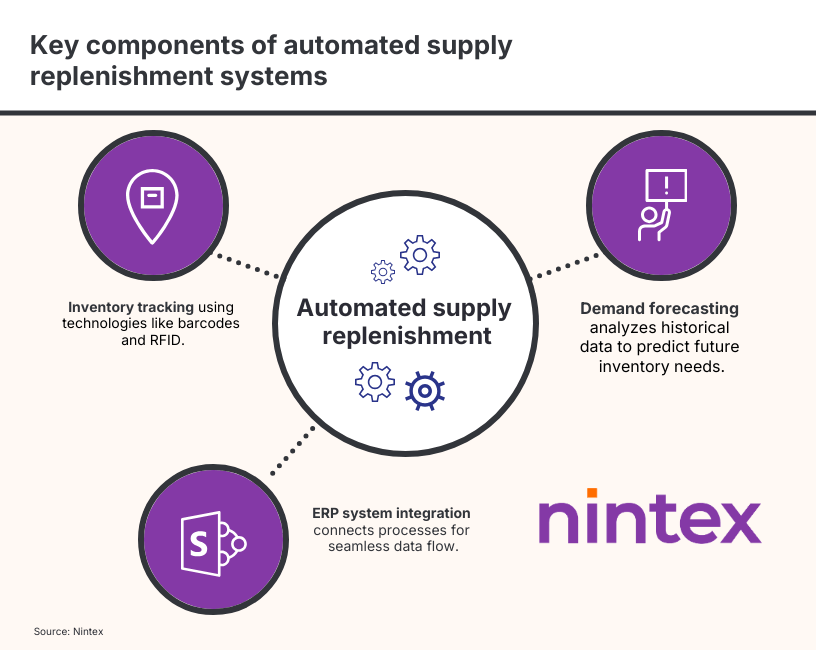

Key components include inventory tracking technologies like barcode scanners and RFID systems, which provide real-time data on stock levels. Demand forecasting algorithms analyze historical sales data to predict future inventory needs accurately. These systems often integrate with enterprise resource planning (ERP) software for seamless communication across business functions.

Manual replenishment systems require human intervention to monitor stock levels and place orders, leading to potential errors, delays, and inefficiencies. In contrast, automated systems continuously monitor stock levels and make replenishment decisions based on predefined parameters. This reduces staff workload and minimizes human error, resulting in a more reliable and efficient supply chain process.

Benefits of implementing automated supply replenishment

Implementing automated supply replenishment systems can result in significant cost savings and efficiency improvements. Automation reduces the time and resources spent on manual inventory tracking and ordering, allowing staff to focus on more strategic tasks.

One of the most critical advantages is the reduction of stockouts and overstock situations. Automated systems use real-time data and predictive analytics to maintain optimal inventory levels, preventing lost sales and dissatisfied customers due to stockouts, and avoiding increased holding costs and waste from overstocking.

Automated supply replenishment also enhances inventory accuracy and visibility. Improved tracking and reporting provide a clearer picture of stock levels and trends, enabling better decision-making and planning. Businesses can operate more effectively, respond to market changes swiftly, and maintain a competitive edge.

How automated supply replenishment systems work

Automated supply replenishment systems optimize inventory management through sophisticated data collection and tracking. These systems gather real-time data on stock levels, sales patterns, and usage rates, providing businesses with an accurate view of their inventory status. Advanced analytics help identify trends and anticipate demand, ensuring the right products are available at the right time.

A key feature is the trigger mechanism for replenishment orders. When inventory levels fall below predefined thresholds, the system automatically generates purchase orders. This proactive approach helps prevent stockouts and minimizes excess inventory, leading to more efficient resource management and reduced carrying costs.

These systems can integrate with existing inventory management solutions, enhancing functionality without a complete overhaul of current processes. Integration with ERP and inventory systems ensures smooth data flow, providing a comprehensive view of inventory across all locations. This streamlines operations, improves accuracy, and ultimately enhances customer satisfaction by ensuring product availability.

Best practices for automated supply replenishment

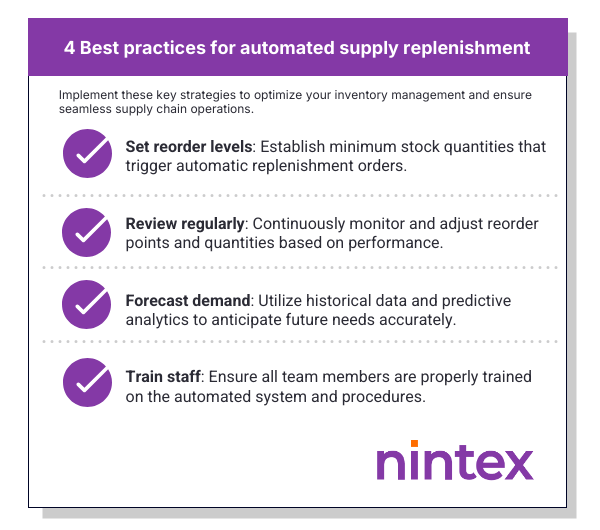

Implementing an effective automated supply replenishment system requires attention to detail and adherence to best practices. One key strategy is setting optimal reorder levels and safety stock by calculating the minimum stock levels needed to meet demand while avoiding overstock situations. Analyzing historical sales data and forecasting future demand helps establish precise reorder points that trigger replenishment before inventory runs out.

Regularly reviewing and adjusting inventory parameters is essential. Market conditions, seasonal trends, and consumer behaviors can change, requiring periodic reassessment of inventory thresholds. Utilizing analytics and reporting tools within your automated system allows businesses to maintain flexibility and adapt to fluctuations, ensuring responsiveness to customer needs.

Training staff on the system and processes is crucial for maximizing effectiveness. Employees should understand how the system operates, the significance of the data it generates, and how to troubleshoot issues. Ongoing training and support foster continuous improvement and help staff stay aligned with inventory management goals.

Challenges in automated supply replenishment

Automated supply replenishment systems offer significant advantages but come with challenges. One common pitfall is reliance on inaccurate data, which can lead to overstocking or stockouts. Regular inventory data audits and real-time updates through system integration can enhance data reliability.

Technical issues and system maintenance are also critical concerns. Automated systems require regular updates and troubleshooting to maintain performance. Businesses should train staff to handle minor technical issues and partner with a reliable IT service provider for complex problems. Regular maintenance checks can prevent unexpected downtimes and ensure smooth operation.

Balancing automation with human oversight is essential. While automation streamlines processes, human oversight is necessary for nuanced decisions. Regular reviews of automated processes and outcomes can identify areas for improvement and ensure alignment with business goals. A collaborative environment between technology and personnel helps harness the benefits of automated supply replenishment systems.

Future trends in automated supply replenishment

The landscape of automated supply replenishment systems is evolving, driven by emerging technologies in inventory management. Innovations such as Internet of Things (IoT) devices enable real-time data collection, allowing businesses to monitor stock levels and usage patterns more effectively. This connectivity leads to smarter inventory decisions, minimizing waste and ensuring product availability.

Artificial intelligence (AI) and machine learning analyze vast amounts of data to accurately predict demand, aligning replenishment processes with customer needs. Predictive analytics help optimize inventory levels, reducing excess stock while preventing shortages that can disrupt operations.

As these technologies mature, supply chain practices will become more integrated with other business processes, creating a seamless flow of information across departments. This integration will enhance collaboration and enable agile responses to market changes. Increased reliance on automated systems will drive businesses to adopt more sophisticated strategies, focusing on sustainability and efficiency to meet consumer expectations.

Common problems and solutions

| Problems | Solutions |

|---|---|

| Stockouts | Automated replenishment orders |

| Overstocking | Real-time inventory monitoring |

| Human error in manual tracking | Reduced manual intervention |

| High inventory carrying costs | Optimized inventory levels |

| Inaccurate inventory data | Regular data audits and integration |

FAQ

Q. What is an automated supply replenishment system?

A. An automated supply replenishment system is a technology-driven solution that streamlines inventory management by automatically monitoring stock levels and placing replenishment orders.

Q. How does an automated supply replenishment system work?

A. These systems gather real-time data on stock levels, sales patterns, and usage rates. When inventory falls below predefined thresholds, the system automatically generates purchase orders to replenish stock.

Q. What are the benefits of automated supply replenishment systems?

A. Benefits include cost savings, reduced stockouts and overstock situations, enhanced inventory accuracy and visibility, improved operational efficiency, and better decision-making.

Q. What challenges do businesses face with automated supply replenishment?

A. Challenges include reliance on accurate data, technical issues and system maintenance, and the need to balance automation with human oversight.